- Find us here

-

Friederikenstr. 100,

26871 Papenburg - (00 49) 04961-9890-0

- Find us here

-

Fresenburger Weg 4,

49779 Niederlangen - (00 49) 05939-94064-0

- Find us here

-

Robert-Bosch-Str. 9,

48480 Spelle - (00 49) 05977-47596-0

- Find us here

-

Rottweg 17,

48683 Ahaus - (00 49) 2561-9384-0

LISSMAC | SBM-L 1000 G1S2

- Other Metal Processing

- Other machines

- Deburring Machine

For telephone enquiries: (00 49) 05939-94064-0

or maschinen@heinz-sanders.de

Niederlangen Branch

Details

- Control type

- konventionell

- Year of manufacture

- 2025

- Stock number

- 1125-2230011

- Manufacturer

- LISSMAC

- Storage location

- 49779 Niederlangen

Technical specifications

- working width:

- 1000 mm

- workpiece width - max.:

- 0,5 - 50 mm

- sandingbelt width:

- -- mm

- weight of the machine ca.:

- 2,5 t

Description

With the SBM-L 1000 G1S2, which works in the dry process, in alternating

operation

Steel, stainless steel and aluminum can be machined. She deburrs and rounds

the edges on the outer and inner contours of punched, laser, fine plasma or

water jet cut workpieces with a thickness of up to 50 mm

on both sides in just one operation.

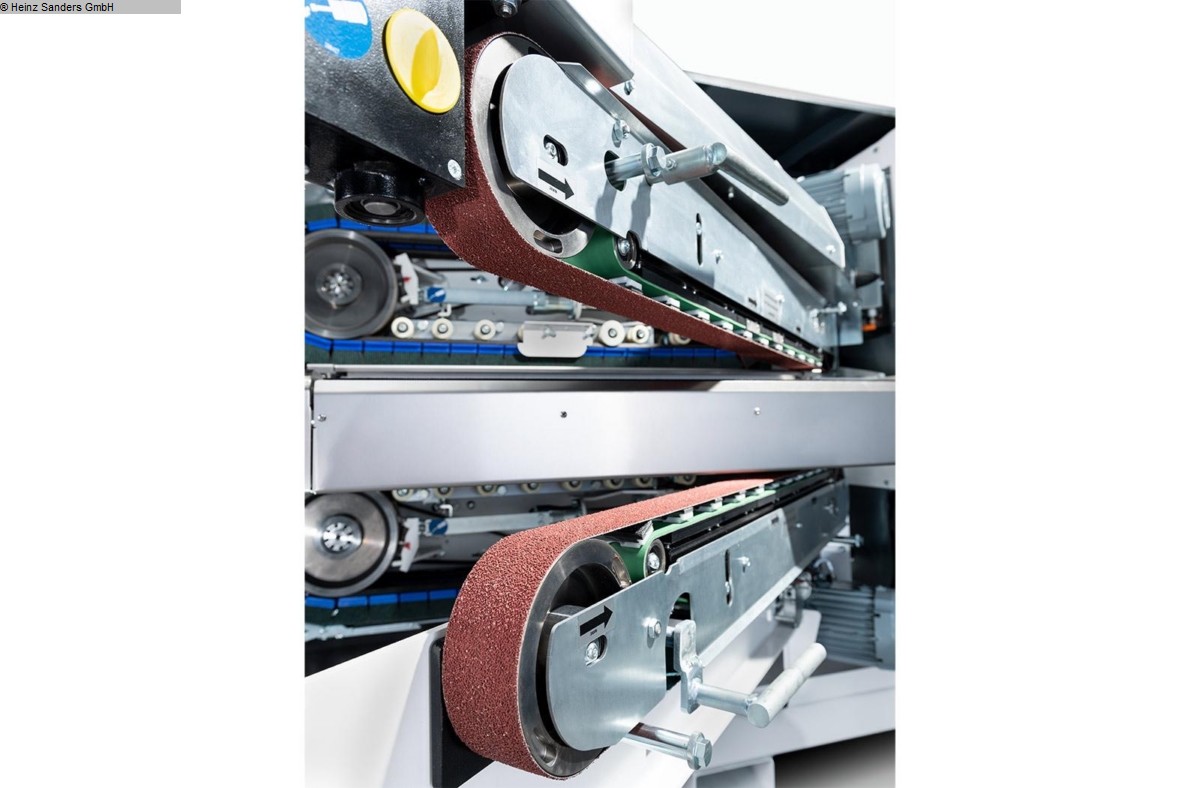

* Two sanding units, 1 each on the top and bottom, remove spatter

and slight burrs on outside and inside edges of sheet metal.

* A total of four sanding belts, 2 each on the top and bottom

Underside, process the sheets on both sides at the same time. here

All edges are softened or rounded, depending on the tool settings.

* Machining on both sides saves time-consuming turning of the workpieces and

edit twice.

* All pairs of aggregates can be switched on/off separately depending on the

application as well as

to be set.

* Including Siemens S7 control:

- Easy and comfortable operation through intuitive user interface

- High operating security through 3 password-protected user levels

- Integrated program memory

- USB / RJ 45 interface for data exchange or connection of external

Components (e.g. barcode scanner)

- Direct entry of material thickness via touch panel

- All axes automatically adjust to preselected material thickness

- Standby position for deactivated aggregates

- Service-friendly (e.g. plain text error messages)

consisting of:

- Grinding machine SBM-L 1000 G1S2 (kit)

- 4x sanding belts SBM 1000 with bar P60 SiC

- Sanding belt SBM-L 1000 L=3125 B=70 P80 Cubitron 2 784F

- SBM-L tool wear compensation Siemens S7

- DDE 3002 dry suction

- Standard piping DDE 3002 / WDE 3002 for SMD 123, SMD 133

** Further detailed technical data on request. The machine is in stock

Niederlangen available immediately.**