- Find us here

-

Friederikenstr. 100,

26871 Papenburg - (00 49) 04961-9890-0

- Find us here

-

Fresenburger Weg 4,

49779 Niederlangen - (00 49) 05939-94064-0

- Find us here

-

Robert-Bosch-Str. 9,

48480 Spelle - (00 49) 05977-47596-0

Machines

For telephone enquiries: (00 49) 05939-94064-0

or maschinen@heinz-sanders.de

Niederlangen Branch

Excavators/crushing plants

Boring mills / Machining Centers / Drilling machines

Grinding machines

Lathes

Machine tools grinding machines

Machining centre

Milling machines

Presses

Saws

Sheet metal working / shaeres / bending

Storing sytems

Threading machines

Welding machines

Other accessories for machine tools

Other attachments

Other machines

Sonstige

Supply Machines

Conveying and storage technology

Workshop equipment

Lacquering, waxing, spraying booths

Window production: wood, pvc and aluminum

ERMAK

HVR CNC 3100-6

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Sheet metal working / shaeres / bending

- Kategorie 3:

- Plate Shear - Hydraulic

-------------------------------------------------- --------- heavy electr. / hydraulic CNC swing cut shears * with CYBELEC CNC touch screen control * with electr. / hydr. Kerf adjustment -------------------------------------------------- --------- Furnishing: - CNC electr. / hydraulic swing cut shears - CYBELEC CNC touch screen controller, model CybTouch 8 * Backgauge preselection - X axis * Cutting gap adjustment * Number of pieces * Cutting length limitation * Material preselection, including sheet thickness * Cutting line lighting - motorized backgauge, travel = 1,000 mm (X axis) * on ball screws * autom. Can be folded up at max.travel, for longer cuts - 1x side stop - 2x front support arms - Ball rollers in the front support table - hinged finger protection, with safety switch - BOSCH / HOERBIGER hydraulic system - SIEMENS electrical system - light barrier behind the machine (safety device) - foot switch - CE mark / declaration of conformity - User manual: machine and control in German

- Lagernummer:

- 1125-2320003

- sheet width:

- 3100 mm

- plate thickness:

- 6 mm

- rear stop:

- 1000 mm

- throat:

- 350 mm

MEBA - VOLLAUTOMAT

MEBAeco 410 DGA 2300

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Saws

- Kategorie 3:

- Band Saw

- The ergonomic panel control can be networked and offers various options Option packages * Teleservice for remote maintenance * Setting sawing programs in the AV * Import of sawing programs from CAD with DSTV interface and data export - Automatic material feed: - In a compact design for shorter sections or with flexible insertion tongs Available in almost all lengths - Exact positioning of the material using servo positioning technology - Pioneering electric saw feed with ball screw: - highest cutting performance and quality, while being gentle on the saw band - Consistent use of the most modern recirculating ball bearing systems: - smooth-running, highly resilient, low-maintenance and play-free - Unique and patented double miter system: - Material is always clamped at right angles Furnishing: - Automatic cutting pressure and feed monitoring - Frequency-controlled AC drive 15-150 m/min, 5.5 kW - Hydraulic material full stroke clamping - Automatic movement of the vices - Saw frame height adjustment automatically - Minimum speed and saw band monitoring - Electric miter tilting via servo motor - Visualized program input with CNC control - Integrated MEBA pliers insertion system from 5-2300 mm per stroke with integrated roller conveyor *Special equipment: - Laser light for cutting line display/marking saws - Chip brush driven - Micro dosing system - Clamping pressure regulation - Material bundle tension - Job menu - Material database - Zero stop - Scraper belt conveyor for optimal chip disposal, 2000 mm long - Cutting progress control

- Lagernummer:

- 1125-2170006

- cutting diameter:

- 410 mm

- saw band length:

- 5800 x 41 x 1,3 mm

- table height:

- 750 mm

- capacity 90 degrees: flat:

- 700 x 410 mm

ERMAK

CNC HGD 3100-10 HH MONO

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Sheet metal working / shaeres / bending

- Kategorie 3:

- Plate Shear - Hydraulic

-------------------------------------------------- --------- heavy electr. / hydraulic CNC swing cut shears * with CYBELEC CNC touch screen control * with electr. / hydr. Kerf adjustment -------------------------------------------------- --------- Furnishing: - CNC electr. / hydraulic swing cut shears - CYBELEC CNC touch screen controller, model CybTouch 8 * Backgauge preselection - X axis * Cutting gap adjustment * Number of pieces * Cutting length limitation * Material preselection, including sheet thickness * Cutting line lighting - motorized backgauge, travel = 1,000 mm (X axis) * on ball screws * autom. Can be folded up at max.travel, for longer cuts - 1x side stop - 2x front support arms - Ball rollers in the front support table - hinged finger protection, with safety switch - BOSCH / HOERBIGER hydraulic system - SIEMENS electrical system - light barrier behind the machine (safety device) - foot switch - CE mark / declaration of conformity - User manual: machine and control in German

- Lagernummer:

- 1125-2320005

- sheet width:

- 3100 mm

- plate thickness:

- 10 mm

- rear stop:

- 1000 mm

- throat:

- 350 mm

HSG

G3015X 6kW

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Sheet metal working / shaeres / bending

- Kategorie 3:

- Laser Cutting Machine

CUTTING CAPACITY: STRUCTURAL STEEL 25 mm STAINLESS STEEL 15 mm ALUMINUM 12mm BRASS 8mm COPPER 8mm MACHINE AXES: 4 axes [X, Y, Z, U ] CUTTING HEAD: Precitec ProCutter CAD/CAM SOFTWARE: LANTEK EXPERT CUT *4 servo motors for all axial movements *CNC CONTROL PANEL 15 5 touch screen *IPG laser sources and coolers integrated *Precitec Procutter cutting head system *AIR FILTER (compressed air filter) *CONVEYOR BELT under cutting area *Closed housing and specially coated filter protection windows *LOADING / DISCHARGING SYSTEM *PROPORTIONAL GAS AND PIPE SYSTEM

- Lagernummer:

- 1125-2500029

- table length:

- 3000 mm

- table width:

- 1500 mm

- burner heads:

- 1

- Control:

- CNC

MEP - Halbautomat

SHARK 512 SXI evo

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Saws

- Kategorie 3:

- Band Saw

Powerful miter band saw for cuts from 60 ° right to 60 ° Left With saw band 34 x 1.1 mm (5.5 kW frequency converter, 4 kW belt drive motor) Electro-hydraulic semi-automatic machine with microprocessor control Functionality: -Semi-automatic operation (start / stop position of the saw bow is controlled via the Keyboard programmed. Vice closes / opens automatically, saw bow is automatically returned to the beginning of the cut) Features: -Stable, torsion-resistant and low-vibration saw frame made of cast steel - Carbide band guides for maximum cutting precision. Front, adjustable Tape guide holder on linear guides for easy, fast and accurate Adjustment for the cutting area -Large dimensioned deflection discs, adjustable made of cast steel -Large, easily adjustable and mounted turntable, by means of central axis bolts centered turntable with precision stops at 0 ° / 45 ° / 60 ° and Table clamp for intermediate angles -Control panel, swiveling, contains all operating elements -Control with soft-touch keyboard, backlit display for display all machine parameters and messages in plain text, including: -Number of cuts (piece counter), cutting time, power consumption of the Saw band motor, saw band tension in kg (minimum band tension = 900 kg), Saw frame position (Y-axis), alarms / faults (description and causes), Diagnosis -Saw band tension with band tension control and indication on the display by means of electronic converter -Frequency converter for stepless drive of the tool -Underframe with lockable door -Large, laterally pull-out chip tray and coolant container with 2 powerful coolant pumps, flushing nozzle with volume control for Removal of chips from the work area -Coolant gun to clean the machine -Vise with quick adjustment and exchangeable clamping and Stop jaws, lateral adjustment on linear guides - Chip removal brush, driven, for cleaning the saw band -Machine is prepared for all options (see price list). (Electric wire, Software etc.) Standard equipment: -Bi-metal saw band -Adjustable length stop 600 mm with millimeter scale Tool kit -Detailed operating instructions, maintenance manual, circuit diagrams and Exploded view -Adapter for supply roller conveyor incl. 1 support roller - Entry option for forklift / pallet truck transport

- Lagernummer:

- 1125-6614

- cutting diameter:

- 330 mm

- saw band length:

- 4640 mm

- cutting width:

- 510 mm

- capacity 90 degrees: flat:

- 510 x 320 mm

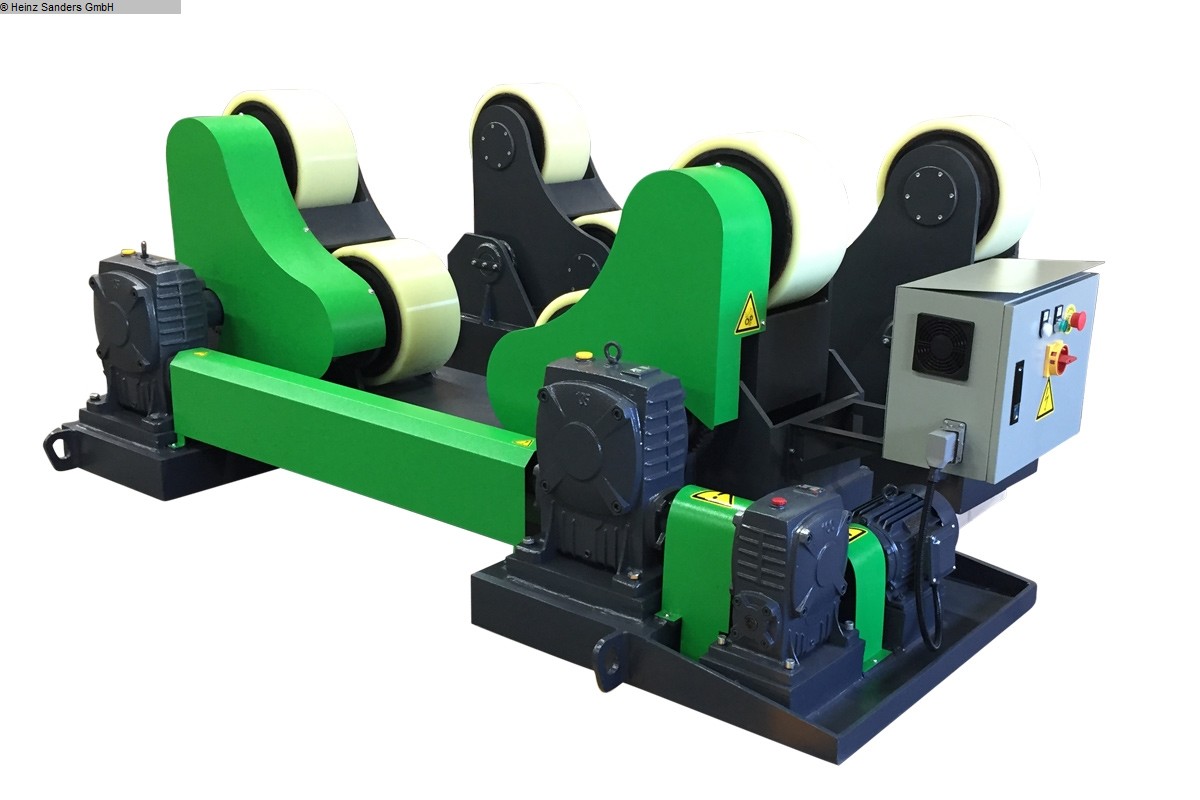

DUMETA

D-TLRS-5 SET

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Sheet metal working / shaeres / bending

- Kategorie 3:

- Vessel Turning Unit

- For machining cylindrical workpieces - Flat frame - Castors with polyurethane coating - Clear controls - Infinitely variable speed - The control electronics are of a robust and closed housing protected - With foot switch for start/stop - Drive with DC electric motors and gears

- Lagernummer:

- 1125-2450013

- weight max.:

- 5000 kg

- workpiece diameter:

- 250 - 2500 mm

- total power requirement:

- 0,75 kW

- table turning speeds:

- 100 - 1000 mm/min

METALLKRAFT

GS 1200-24 E inkl. Unterbau

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Threading machines

- Kategorie 3:

- Thread-Cutting Machine

Electric tapping machine / 4450124SET Fast and precise thread cutting with freely positionable swivel arm - The machine head can be swiveled from 0 to 90 degrees - Quick change chuck with slip clutch for safe thread cutting without Risk of breakage - Right-left rotation can be selected on the machine head - Setting the parameters via touch display on the swivel arm - Both manual and automatic switching from forward to backward to reaching the entered Incl. 1 each GT24 M6, M8, M10, M12, M14, M16, M18, M20, M22-24 tapping chuck Substructure 900 x 600 x 875 mm

- Lagernummer:

- 1125-7362

- thread dia.:

- M6 - M24 mm

- turning speeds:

- 200 U/min

- radius:

- 1200 mm

- angle adjustable from - to:

- 0 - 90 Grad

ERMAK

CNC HGD 3100-10

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Sheet metal working / shaeres / bending

- Kategorie 3:

- Plate Shear - Hydraulic

-------------------------------------------------- --------- heavy electr. / hydraulic CNC swing cut shears * with CYBELEC CNC touch screen control * with electr. / hydr. Kerf adjustment -------------------------------------------------- --------- Furnishing: - CNC electr. / hydraulic swing cut shears - CYBELEC CNC touch screen controller, model CybTouch 8 * Backgauge preselection - X axis * Cutting gap adjustment * Number of pieces * Cutting length limitation * Material preselection, including sheet thickness * Cutting line lighting - motorized backgauge, travel = 1,000 mm (X axis) * on ball screws * autom. Can be folded up at max.travel, for longer cuts - 1x side stop - 2x front support arms - Ball rollers in the front support table - hinged finger protection, with safety switch - BOSCH / HOERBIGER hydraulic system - SIEMENS electrical system - light barrier behind the machine (safety device) - foot switch - CE mark / declaration of conformity - User manual: machine and control in German

- Lagernummer:

- 1125-7348

- sheet width:

- 3100 mm

- plate thickness:

- 10 mm

- rear stop:

- 1000 mm

- throat:

- 350 mm

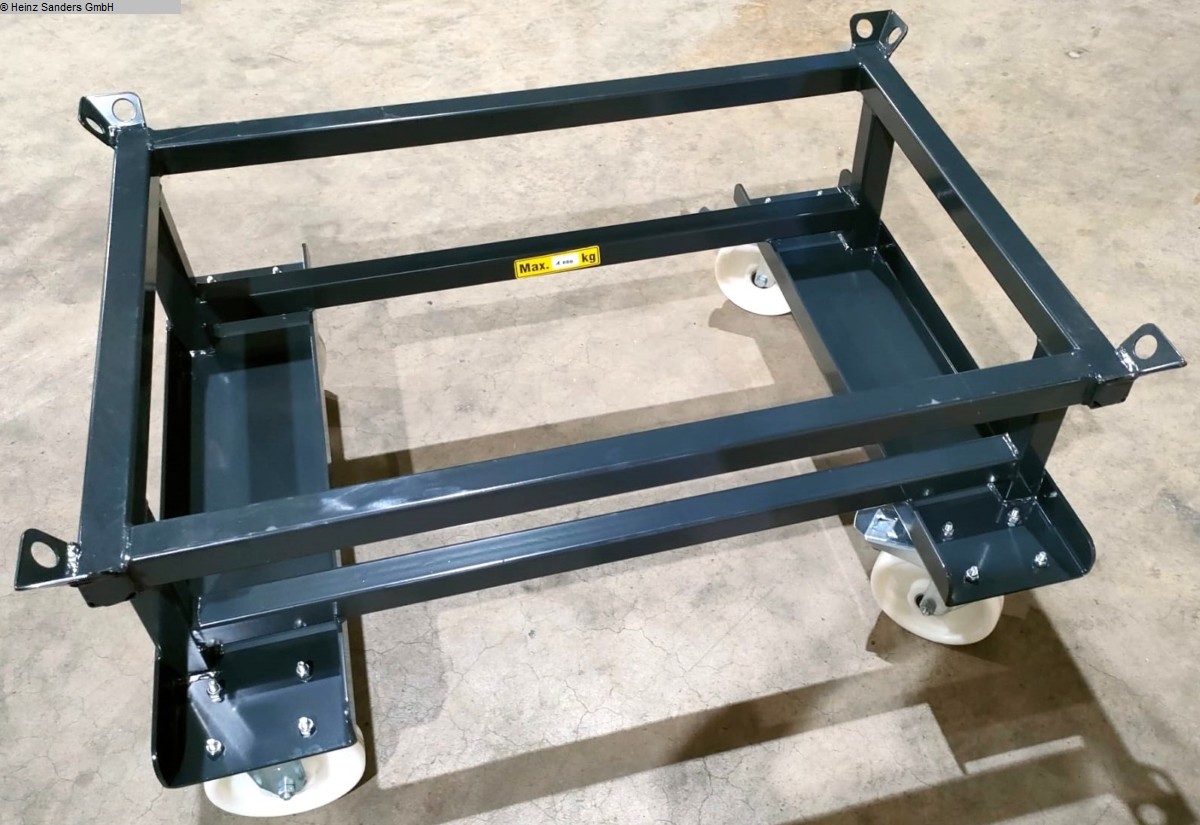

Palettenrahmen Aufsatzrahmen

fuer EUROPALETTE

- Kategorie 1:

- Tools and industrial equipment

- Kategorie 2:

- Conveying and storage technology

- Kategorie 3:

- Other storage technology

*While stocks last* 4x hinges the pallet frames are foldable Weight: approx. 9.5 kg for 1200x800x200 mm

- Lagernummer:

- 1125-1163

KLOPP

FWU 13/2 + E2

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Milling machines

- Kategorie 3:

- Universal Milling Machine

- horizontal + vertical milling spindle - Cooling device - swiveling table - Chip tray - Feed X/Y/Z - axis infinitely adjustable 8-1680 mm/min - Rapid traverse X/Y/Z - axis 4000 mm/min - Control HEIDENHAIN TNC 124 - Operating hours: 4764 hours - Machine light - Machine feet - Operation manual

- Lagernummer:

- 1125-3130033

- x-travel:

- 1150 mm

- y-travel:

- 350 mm

- z-travel:

- 500 mm

- speeds:

- 28 - 1400 U/min

REHNEN

ZEUS

- Kategorie 1:

- Other Machines

- Kategorie 2:

- Other attachments

- Kategorie 3:

- Lift table

- Lagernummer:

- 1125-2540042

- table length:

- 2000 mm

- table width:

- 1000 mm

- stroke height:

- 400 - 1010 mm

- weight max. in kg:

- 300 kg

METALLKRAFT

MSBM 2020-15 C S motorisch

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Sheet metal working / shaeres / bending

- Kategorie 3:

- Folding Machine

Heavy version with motorized drive for the upper and bending beam and segmented upper beam / 3772940 - Foot control enables the sheet metal to be positioned with both hands - The workpiece is clamped and bent using a motorized chain drive - Setting the bending angle manually, reading the angle on a scale ring - Many bending options with segmented upper beam - Exact movement of the bending beam via large flat guides - Heavy, robust welded construction Segment division: 25-30-35-40-45-50-75-100-150-200-200-270-400-400 mm VA steel: 0.8 mm Aluminum: 2.0 mm

- Lagernummer:

- 1125-7078

- sheet width:

- 2020 mm

- plate thickness:

- 1,5 mm

- distance between columns:

- -- mm

- bending angle max. +/-:

- 135 °

Monforts

KNC 5S

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Lathes

- Kategorie 3:

- CNC Lathe

CNC lathe - cycle controlled

- Lagernummer:

- 1125-3210021

- turning diameter:

- 580 mm

- turning length:

- 3010 mm

- centre height:

- 310 mm

- control:

- MONFORTS CONTROL

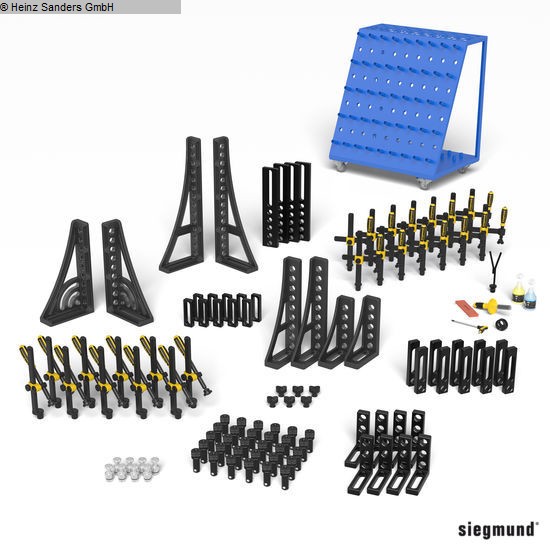

SIEGMUND - ZUBEHOER

SET 1 28er System

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Welding machines

- Kategorie 3:

- Welding Table

consisting of: 4x clamp 280610.N 2x clamp 280630.N 2x prism 280648.1.N 12x bolts 280511 4x stop 280410.N 4x stop 280420.N 2x angle 280110.N 2x angle 280152.N 1x accessory set 283999

- Lagernummer:

- 1125-9283100

- :

- 51 kg

- :

- -- mm

- :

- -- mm

PEDDINGHAUS

Peddimaster 60/80

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Sheet metal working / shaeres / bending

- Kategorie 3:

- Section Shear - Combined

Hydraulic machine with 5 stations so punching, notching, shearing flat iron, angle iron, solid material, punching with hand lever, profile steel side with foot switch. Punching discharge: 510 mm! All performance data refer to a material strength of 450 N / mm². Electric 380 volt

- Lagernummer:

- 1125-3410025

- round bar steel:

- 35 mm

- square edge steel:

- 32 mm

- L-beam:

- 120 x 12 mm

- flat steel:

- 400 x 16 / 200 x 20 mm

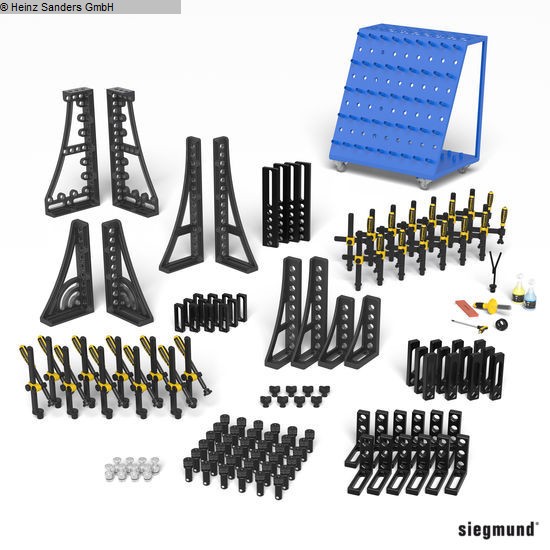

SIEGMUND - ZUBEHOER

SET 4 28er System

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Welding machines

- Kategorie 3:

- Welding Table

consisting of: 14 pieces Professional screw clamp 280610.N 10 pieces Professional screw clamp 280630.N 6 pieces Vario prism Ø 50 135 ° 280648.1.N 30 quick release bolts 280511 8 magnetic clamping bolts 60 280 740 10 pieces universal stop 150 L 280410.N 10 pieces universal stop 225 L 280420.N 4 pieces universal stop 500 S 280430.N 8 stop and clamping angles 175 L 280110.N 2 stop and clamping angles 300 G 280152.N 2 stop and clamping angles 500 G 280162.N 1 piece stop and clamping angle 500 G with angle of rotation left 280164.N 1 piece stop and clamping bracket 500 G with right rotation bracket 280165.N 1 piece stop and clamping bracket 750 G left 280166.N 1 piece stop and clamping bracket 750 G right 280167.N 1 piece tool trolley 280910

- Lagernummer:

- 1125-9283400

- :

- 282 kg

- :

- -- mm

- :

- -- mm

Dumeta

D-HB-6

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Welding machines

- Kategorie 3:

- Rotary Welding Table

The D-HB tilt and turn tables are very stable due to their heavy construction and therefore particularly suitable for heavy and precise Positioning activities and circular welding work. Features: - Easy installation - Increase in production is made possible - Improvement of the welding quality through optimal positioning and Cruise control - Reduction of crane hours and handling time, during which the Improved occupational safety. - Self-locking gear, therefore no leading or trailing behind with eccentric burden - Electronic components from Schneider, Siemens and Delta - Frequency-controlled stepless speed of the turntable - High stability due to the robust construction - CE certificate - The D-HB series includes a remote control with foot pedal for left-right / Start-stop.

- Lagernummer:

- 1125-5340

- table diameter:

- 700 mm

- table load:

- 0,6 t

- swivelling range:

- 0-90 Grad

- excentricity:

- 200 mm

DALEX

SL25-1

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Welding machines

- Kategorie 3:

- Spot Welding Machine

Rated power ( 50% ED ) : 25 kVA maximum short-circuit current: 22.4 kVA Maximum welding power : 107 kVA Cooling water quantity : 4 l/min Electrode arm Ø : 45 mm Electrode holder Ø : 25 mm Projection : 460 mm Electrode force : 17 to 278 daN Machine weight : 240 kg Dimensions : 1100 x 750 x 1250 mm incl. foot switch

- Lagernummer:

- 1125-3450011

- current capacity:

- - kVA

- throat:

- - mm

- contact pressure capacity:

- - kp

HERA

HSS III / 3100 x 2,0

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Sheet metal working / shaeres / bending

- Kategorie 3:

- Plate Shear - Hydraulic

Furnishing: - electric back gauge 750 mm - front support plates with ball rollers - Light barrier behind the machine - Hydraulic cutting adjustment - Cutting gap regulation via handwheel - LED cutting edge lighting - 1x side stop with scale 1500 mm - 1x freely movable foot switch - Operation manual

- Lagernummer:

- 1125-3320052

- sheet width:

- 3100 mm

- plate thickness:

- 2 mm

- rear stop:

- 1000 mm

- cutting angle:

- 1°06 °

PLACKE

HQPB M-6

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Sheet metal working / shaeres / bending

- Kategorie 3:

- Hydr. pressbrake

Basic version as a C-frame Compact table model Ideal for prototypes and small series Very short setup time Functionally simple Wide range of applications Low noise level Low energy consumption Easy handling including special equipment: - CNC control DELEM DA 41T

- Lagernummer:

- 1125-2300009

- pressure:

- 150 t

- chamfer lenght:

- 3100 mm

- distance between columns:

- 2600 mm

- dayligth:

- 450 mm

SIEGMUND - ZUBEHOER

SET 5 28er System

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Welding machines

- Kategorie 3:

- Welding Table

consisting of: 14 pieces professional screw clamp 10 pieces Professional screw clamp 45 ° / 90 ° 8 pieces Vario prism Ø 50 135 ° 36 quick release bolts without groove, double 8 magnetic clamping bolts 60 12 pieces universal stop 150 L 12 pieces universal stop 225 L 4 pieces universal stop 500 S 12 stop and clamping angles 175 L 2 stop and clamping angles 300 G 2 pieces of stop and clamping angle 500 G 1 stop and clamping bracket 500 G with 1 stop and clamping bracket 500 G with 1 piece stop and clamping bracket 750 G left 1 piece stop and clamping bracket 750 G right 1 piece stop and clamping bracket 800 GK left 1 piece stop and clamping bracket 800 GK right 1 piece tool trolley

- Lagernummer:

- 1125-9283500

- :

- 325 kg

- :

- -- mm

- :

- -- mm

SIEGMUND - ZUBEHOER

SET 2 28er System

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Welding machines

- Kategorie 3:

- Welding Table

Item No. 283200 / Sanders item no. S9489283200 consisting of: 6x clamp 280610.N 4x clamp 280630.N 4x prism 280648.1.N 18x bolt 280511 4x magnetic bolts 280740 6x stop 280410.N 6x stop 280420.N 4x angle 280110.N 2x angle 280152.N 2x angle 280162.N 1x accessory set 283999

- Lagernummer:

- 1125-9283200

- :

- 92 kg

- :

- -- mm

- :

- -- mm

FASTI

211 - 25 - 3

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Sheet metal working / shaeres / bending

- Kategorie 3:

- Folding Machine

- lateral protective wall - 1x free moving footswitch - Electrically controlled back gauge

- Lagernummer:

- 1125-3350014

- sheet width:

- 2540 mm

- plate thickness:

- 3,0 mm

- distance between columns:

- 2500 mm

- back stop - adjustable:

- 1000 mm

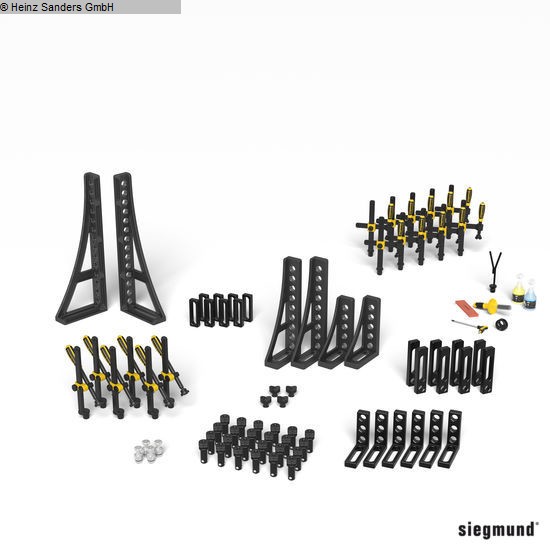

SIEGMUND - ZUBEHOER

SET 3 28er System

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Welding machines

- Kategorie 3:

- Welding Table

consisting of: 10x screw clamp standard 280610.N 6x screw clamp 45 ° / 90 ° 280630.N 4x prism Ø 50 mm 280648.1.N 24x quick release bolts 280511 4x magnetic clamping bolts 280740 8x universal stop 150 L 280410.N 8x universal stop 225 L 280420.N 6x stop and clamping angle 175 L 280110.N 2x stop and clamping angle 300 G 280152.N 2x stop and clamping angle 500 G 280162.N 1x angle 280166 + 67.N 1x accessory set 283999

- Lagernummer:

- 1125-9283300

- :

- 145 kg

- :

- -- mm

- :

- -- mm

SANDERS

SLB 15 to - 2000 mm

- Kategorie 1:

- Other Accessories for Machine Tools

- Kategorie 2:

- Other accessories for machine tools

- Kategorie 3:

- axle stand

- Lagernummer:

- 1125-3867E

- :

- 15000 kg

- height:

- 790 - 1350 mm

- width:

- 2000 mm

- :

- ja

SIEGMUND

Professional 750 3000 x 1500

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Welding machines

- Kategorie 3:

- Welding Table

The Professional 750 table article no. 4-280040.P 3000x1500x200 mm has a Hole arrangement in a 100 mm grid on the table top and a parallel one Hole arrangement in 50 mm grid on the sides. The holes have a diameter of 28 mm. The table has one Material thickness of approx. 24.5-27 mm and is made from high quality steelS355J2 + N manufactured. Grid lines at a distance of 100 mm make it easier for you to set up your Contraption. The welding tables are provided with a scale as standard. Including 6x feet basic equipment 650 Article no. 280858.X

- Lagernummer:

- 1125-4772

- table length:

- 3000 mm

- table width:

- 1500 mm

- table height:

- 200 mm

- weight of the machine ca.:

- 1,55 t

BERG & SCHMID

VKS 370

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Saws

- Kategorie 3:

- Cold Circular Saw

-The powerful, 2-stage gear was specially designed for cuts in solid material designed -The user has a total of 4 blade speeds for optimal adjustment the material available -The large bearing rotary table with internal table clamping and Precision stops at 0/45/60° ensure quick adjustability miter cuts -The vice with quick clamping (optional is a pneumatic one Vise = MA, available) is with screwed vise jaws Mistake. With their ribbing, these ensure optimal hold of the workpiece -Underframe with lockable door, chip drawer and removable Coolant pan with electric coolant pump -Chip removal brush

- Lagernummer:

- 1125-2160003

- saw blade diameter:

- 370 x 3,0 x 40 mm

- cutting diameter:

- 120 mm

- stroke:

- -- mm

- capacity 90 degrees: square:

- 100 mm

SIEGMUND

Professional 750 DR 2400 x 120

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Welding machines

- Kategorie 3:

- Welding Table

The table Professional 750 Article no. 4-280030.PD 2400x1200x200 mm has a diagonal hole arrangement on the table top and a parallel hole arrangement in 50 mm grid on the sides. The holes have a diameter of 28 mm. The table has a material thickness of about 24.5-27 mm and is made of high quality steel S355J2 + N. Grid lines at a distance of 100 mm make it easier for you to set up your device. The welding tables are provided with scale as standard. Including 4x feet Basic equipment 650 Article no. 280858.X

- Lagernummer:

- 1125-5183DR

- table length:

- 2400 mm

- table width:

- 1200 mm

- table height:

- 200 mm

- weight of the machine ca.:

- 1,0 t

SIEGMUND

Professional 750 2400 x 1200

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Welding machines

- Kategorie 3:

- Welding Table

The table Professional 750 Article no. 4-280030.P 2400x1200x200 mm has a hole arrangement in the 100 mm grid on the table top and a parallel hole arrangement in the 50 mm grid on the sides. The holes have a diameter of 28 mm. The table has a material thickness of about 24.5-27 mm and is made of high quality steel S355J2 + N. Grid lines at a distance of 100 mm make it easier for you to set up your device. The welding tables are provided with scale as standard. including 4x feet Basic equipment 650 Article no. 280858.X

- Lagernummer:

- 1125-5183

- table length:

- 2400 mm

- table width:

- 1200 mm

- table height:

- 200 mm

- weight of the machine ca.:

- 1,0 t

SANDERS

3000 x 600 mm

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Saws

- Kategorie 3:

- Roller tracks / stop systems

- straight version - stable construction - high load-stable stability - Height-adjustable feet

- Lagernummer:

- 1125-5007b

- :

- 3000 mm

- Working width:

- 600 mm

- Wheel width:

- 600 mm

- roll diameter:

- 90 mm

GECAM

EASY T

- Kategorie 1:

- Other Metal Processing

- Kategorie 2:

- Other machines

- Kategorie 3:

- Deburring Machine

The "Easy T" is the cost-effective alternative to the conventional ones grinding and deburring machines. His head consisting of a grinding wheel and a flap brush, can be swiveled by 180°. Thus, a faster Switching between the aggregates possible. Due to the weight-bearing arm the head can be easily moved over the workpiece. The result is one even edge rounding. The pad also prevents slipping of the smallest components. Furnishing : - Deburring and rounding of laser-cut or stamped sheet metal parts - Grinding head, consisting of a grinding wheel & a flap brush, can be swiveled by 180° - Working area 800 x 1300 mm - Weighted arm for easy pivoting - non-slip table pad - Ergonomic operation of the machine with the help of push buttons "On/Off" - Grinding head with infinitely variable speed via frequency converter - Handle for ergonomic handling

- Lagernummer:

- 1125-3230011

- diameter:

- 150 mm

- workpiece length:

- 1300 mm

- work piece width:

- 800 mm

- max. dia. of grinding wheel:

- 150 mm

ERMAK

SPEED BEND PRO 3.220

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Sheet metal working / shaeres / bending

- Kategorie 3:

- Hydr. pressbrake

HIGH-SPEED hydraulic press brake with increased installation height increased cylinder stroke increased projection -------------------------------------------------- ------- Furnishing: - DELEM CNC control model DA 66T - swiveling touch screen control unit - 7 controlled axes : Y1 - Y2 - X - R - Z1 and Z2, as well as CNC crowning - electr. controlled backgauge X-axis = 800 mm / R-axis = 250 mm - on ball screws - controlled electr. Stop fingers Z1 + Z2 - split deer foot upper tool Roleri 135.85.R08, "System A" - with additional crowning of the upper wedge - Universal die block - LEUZE light barrier behind d. machine - BOSCH/HOERBIGER hydr. components - SIEMENS - electrical system - FIESSLER AKAS laser protection device in front of the machine (incl. FPSC) - 2 front support arms with SLIDING system (slide bearing) - Double foot control - CE mark / declaration of conformity - Operating manual: Machine and control in German - Safety manual : press brakes Special equipment included: - electric central lubrication

- Lagernummer:

- 1125-2300007

- pressure:

- 220 t

- chamfer lenght:

- 3100 mm

- distance between columns:

- 2600 mm

- dayligth:

- 550 mm

RHTC

PPC 28

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Presses

- Kategorie 3:

- Single Column Press - Hydraulic

- NC control to adjust the piston stroke - Selector switch for manual or semi-automatic operation - Flow control valve and pressure control valve - Integrated pressure gauge - Various tools can be installed on the piston - inside There is a 40 mm hole for attaching the tools

- Lagernummer:

- 1125-7346

- pressure:

- 28 t

- throat:

- 225 mm

- stroke:

- 150 mm

- table surface area:

- 325 x 300 mm

Genie

Scherenarbeitsbuehne GS 3246

- Kategorie 1:

- Other Machines

- Kategorie 2:

- Other attachments

- Kategorie 3:

- working platform

- Operating hours ca. 1000 h - Platform height 10 m - Drive via 24 V electric motor with integrated charger - 2 speed levels - Non-marking tires - Tire size 15 x 5 x 11 ¼, wheelbase 1850 mm - Wheel formula 4x2 - Overall dimensions 2410 x 1170 x 2390 mm (without railing 1790 mm) - Foldable railing - Basket dimensions (in length x width x height) 2260 (+ 900) x 1150 x 1100 mm - Extendable platform 900 mm - Basket and floor controls

- Lagernummer:

- 1125-7423

- weight max. in kg:

- 317 kg

- dimensions:

- Gesamt 2440 x 1180 x 2360 mm

- weight:

- 2790 kg

- work height max.:

- 12000 mm

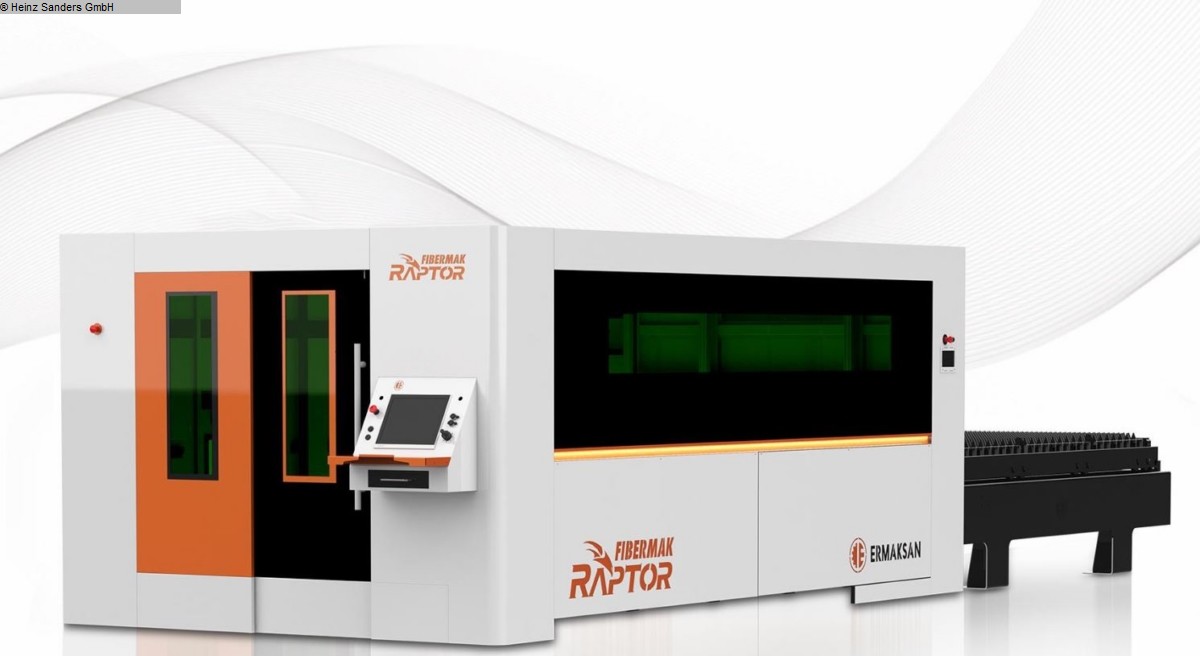

ERMAK

FIBERMAK Thunderbird 6kW

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Sheet metal working / shaeres / bending

- Kategorie 3:

- Laser Cutting Machine

CUTTING CAPACITY: STRUCTURAL STEEL 25 mm STAINLESS STEEL 15 mm ALUMINUM 12mm BRASS 8mm COPPER 8mm MACHINE AXES: 4 axes [X, Y, Z, U ] CUTTING HEAD: Precitec ProCutter CAD/CAM SOFTWARE: LANTEK EXPERT CUT *4 servo motors for all axial movements *CNC CONTROL PANEL 15 5 touch screen *IPG laser sources and coolers integrated *Precitec Procutter cutting head system *AIR FILTER (compressed air filter) *CONVEYOR BELT under cutting area *Closed housing and specially coated filter protection windows *LOADING / DISCHARGING SYSTEM *PROPORTIONAL GAS AND PIPE SYSTEM

- Lagernummer:

- 1125-2500026

- table length:

- 3000 mm

- table width:

- 1500 mm

- burner heads:

- 1

- Control:

- CNC

TEKA

Cartmaster

- Kategorie 1:

- Other Machines

- Kategorie 2:

- Other attachments

- Kategorie 3:

- Suction

- Hose arm 3 m, joints inside - Filter cartridge: dust class M - Pre-filter: baffle plate - Current type: 3Ph+N+PE The filter system --------------------------------------- The mobile filter system of the Cartmaster IFA type is thanks to the automatic Cleaning particularly suitable for welding work with unalloyed and alloyed steels, galvanized material and aluminum with heavy smoke development. It corresponds to the safety requirements for devices Welding fume class "W3" (high-alloy steels with alloy components 30% Nickel-based alloy).If used as intended, the system can be used for the Recirculation mode used because the requirements for the Exceptions according to TRGS 560 are fulfilled. That special developed, dirt-dependent cleaning system ensures a good cleaning behavior of the filter cartridge, so that an optimal suction performance is guaranteed throughout the operation. The cleaned particles fall into a dust collection drawer from which they can then be disposed of. The powerful spiral fan ensures even with saturated Filter cartridges for a high volume flow. The filter media --------------------------------------- A baffle serves as a pre-separator for coarse particles. The filter cartridge installed below (dust class M, degree of separation 99%) filters the finest smoke and dust particles. The cartridge is factory coated which increases the service life. The extraction arm ------------------------ The extraction arm can be moved with the 3 internal joints Position spring support slightly and is in the set position cantilevered. A throttle flap integrated in the extraction hood enables the Flow rate setting.

- Lagernummer:

- 1125-2810012

- :

- 1860 m³/h

- :

- Pressung 2.900 Pa

- :

- 1,1 kW

- filter surface area:

- 10 m²

RAS

GIGAbend 76.30

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Sheet metal working / shaeres / bending

- Kategorie 3:

- Folding Machine

Straight bends are indispensable for perfect bending parts. A robust machine design and a powerful bending cheek resist the bending forces that occur. An intelligent crowning system and 120 tons clamping force of the upper beam ensure perfect bending quality for steel sheets up to 6 mm or stainless steel up to 4 mm. - Rectangle stop

- Lagernummer:

- 1125-3350016

- sheet width:

- 3200 mm

- plate thickness:

- 6,0 mm

- distance between columns:

- 3350 mm

- :

- max. 500 mm

AK BEND

AHS 30/06

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Sheet metal working / shaeres / bending

- Kategorie 3:

- Plate Bending Machine - 4 Rolls

- 2 central rollers driven by an electric motor - Swing-out upper beam - Conical bending device - separate control panel - self-braking main motor - CE mark/Declaration of Conformity Special equipment included in the price: - hardened rollers - Motorized rear roller adjustment

- Lagernummer:

- 1125-2400010

- sheet width:

- mm

- plate thickness:

- mm

- pre-bending:

- :

- 3100 mm

SIEGMUND

Extreme 8.7 3000 x 1500

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Welding machines

- Kategorie 3:

- Welding Table

The table Professional Extreme Article no. 4-280040.X7 2400x1200x200 mm has a hole arrangement in the 100 mm grid on the table top and a parallel hole arrangement in the 50 mm grid on the sides. The holes have a diameter of 28 mm and the table has a material thickness of about 24.5-27 mm. The table top is made of hardened tool steel. The low-loaded sidewalls are still made of steel S355J2 + N for cost reasons. Grid lines at intervals of 100 mm make it easier for you to set up your device. The welding tables are provided with scale as standard. Including 6x feet basic equipment 650 Article no. 280858.X

- Lagernummer:

- 1125-4772X

- table length:

- 3000 mm

- table width:

- 1500 mm

- table height:

- 200 mm

- weight of the machine ca.:

- 1,6 t

SIEGMUND

Extreme 8.7 2400 x 1200

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Welding machines

- Kategorie 3:

- Welding Table

280030.XD7D - Through hardened tool steel X8.7 + plasma nitriding - Material thickness approx. 24.5 27 mm - Sidewall made of high quality steel S355J2+N + plasma nitriding - Bore Ø 28 mm - Holes surface in diagonal grid - Rounded corners, edges and holes - Side panel height 200 mm - Holes in the side wall in the diagonal grid - Including scaling on the surface - Structure reinforced with ribs - Grid lines enable precise build-ups Including 4x feet basic equipment 650 item no. 280858.X

- Lagernummer:

- 1125-5183XDR

- table length:

- 2400 mm

- table width:

- 1200 mm

- table height:

- 200 mm

- weight of the machine ca.:

- 913 kg

LOTZE

273

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Sheet metal working / shaeres / bending

- Kategorie 3:

- Plate Shear - Hydraulic

Furnishing: - electric back gauge 750 mm - front support plates with ball rollers - Light barrier behind the machine - Hydraulic cutting adjustment - Cutting gap regulation via handwheel - LED cutting edge lighting - 1x side stop with scale 1500 mm - 1x freely movable foot switch - Operation manual

- Lagernummer:

- 1125-3320061

- sheet width:

- 2540 mm

- plate thickness:

- 6 mm

- rear stop:

- 900 mm

- down holder:

- 14 Stk

SIEGMUND

Extreme 8.7 DR 3000 x 1500

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Welding machines

- Kategorie 3:

- Welding Table

The table Professional Extreme Article no. 4-280040.XD7D 3000x1500x200 mm has a diagonal hole arrangement on the table top and a parallel hole arrangement in 50 mm grid on the sides. The holes have a diameter of 28 mm and the table has a material thickness of about 24.5-27 mm. The table top is made of hardened tool steel. The low-loaded sidewalls are still made of steel S355J2 + N for cost reasons. Grid lines at intervals of 100 mm make it easier for you to set up your device. The welding tables are provided with scale as standard. Including 6x feet basic equipment 650 Article no. 280858.X

- Lagernummer:

- 1125-4772XDR

- table length:

- 3000 mm

- table width:

- 1500 mm

- table height:

- 200 mm

- weight of the machine ca.:

- 1,6 t

MEP

Shark 332 NC evo

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Saws

- Kategorie 3:

- Band Saw

Powerful miter band saw for cuts from 45 ° right to 60 ° Left CCS (CutControlSystem) for automatic cutting. (Stepless regulation of the Feed and switch-off at the end of the cut) Manual cutting cycle AUTOMATIC CUT: (via selector switch) with stepless settings of the Lowering speed and adjustment of the cutting pressure via compensating spring Stable, torsion-resistant and low-vibration saw frame made of cast steel Large, easily adjustable and mounted turntable, by means of central axis bolts centered turntable with indexing at 0 ° / 45 ° / 60 ° and inside Table clamp for intermediate angles Vice with quick adjustment Carbide band guides for maximum cutting precision Large deflection discs, adjustable, made of cast steel Hydraulic unit for the saw band tension and monitoring with display Manometer (belt tension = 900 kg) Clear switchboard with all controls Underframe with lockable door and removable coolant tray, electric coolant pump Chip removal brush for cleaning the saw band

- Lagernummer:

- 1125-3170085

- cutting diameter:

- 300 mm

- saw band length:

- 3320 mm

- cutting width:

- 330 mm

- :

- 3320 x 27 x 0,9 mm

FALKEN

DPM-K 1070/150 verstellb. Zyli

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Presses

- Kategorie 3:

- Tryout Press - hydraulic

- hydraulic workshop press with adjustable cylinder - Table height adjustment - V-block tool insert - Pressure gauge

- Lagernummer:

- 1125-6964

- pressure:

- 150 t

- stroke:

- 300 mm

- table surface area:

- 1070 x 290 mm

- working width:

- 1070 mm

OPTIMUM

DH 45 G

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Boring mills / Machining Centers / Drilling machines

- Kategorie 3:

- Pillar Drilling Machine

- automatic drill feeds (magnetic clutch) - Height adjustable and angle adjustable table - Movable work table - Integrated cooling system - Powerful engine - 3 hand levers for drilling feed - Safety shield with limit switch - Separate emergency stop - Built-in working lights - Incl. drill chuck 16mm - B16 - Built-in automatic thread cutting.

- Lagernummer:

- 1125-2100029

- bore capacity in steel (diameter):

- 40 mm

- throat:

- 350 mm

- bore stroke:

- 170 mm

- morse taper:

- 4 MK

BERG & SCHMID

GBS 240 Auto CUT

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Saws

- Kategorie 3:

- Band Saw

high-quality processed metal band saw with 2 band speeds, miter up to 60°, automatic cooling and AutoCut feed system - for sawing solid material and profiles execution * High-quality processed and equipped metal band saw for saw cuts best quality * For sawing solid material and profiles made of steel, stainless steel and aluminium * Miter cuts up to 60 degrees left * Saw band speed adjustable in 2 stages * Frame and gearbox made from one piece, very quiet and low-vibration cut * Easy, clear miter adjustment with scale * Quick release vice with quick release lever for easy handling * Length stop * Carbide saw band guide * Electrical monitoring of band tension, band breakage and saw band cover. The saw only runs if there is no fault in the monitoring system. * Ergonomic industrial handle * Electric automatic coolant control * AutoCut system with hydraulic cylinder, feed control, spring pack and limit switch * Large machine bed * Machine base in sheet steel construction with front door AutoCut system * Automatic saw frame lowering via the hydraulic cylinder continuously adjustable feed and limit switch at the end of the cut. * High-speed lowering of the saw frame from the rest position to the workpiece, then switch to normal saw feed (e.g. for scribing). * Manual operation: The hydraulic cylinder works as a brake cylinder (e.g. for release). Due to the brake cylinder, the saw can be moved in any Position to be positioned.

- Lagernummer:

- 1125-6142

- cutting diameter:

- 240 mm

- saw band length:

- 2730 mm

- cutting width:

- 270 mm

- cutting speed:

- 37 + 74 m/min

NKO

B3 Entgrat-/Anfasmaschine

- Kategorie 1:

- Other Metal Processing

- Kategorie 2:

- Other machines

- Kategorie 3:

- Deburring Machine

Maximum bevel width of 3 mm - Mechanically adjustable bevel angle Designed for deburring and chamfering steel parts and workpieces. Processing of different materials. Solid and stable machine construction. * Scale for setting the processing depth * Security cover * Adjustable processing angle * For steel, stainless steel, aluminum and other materials * Precise, massive and overlong mechanical guide - Number of indexable inserts: 5 pieces (four-sided) - Feed: manual

- Lagernummer:

- 1125-2230012

- diameter:

- -- mm

- workpiece length:

- -- mm

- work piece width:

- 0 - 3 mm

- speeds:

- 3600 U/min

OPTIMUM

OPTIturn TH 5620D

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Lathes

- Kategorie 3:

- lathe-conventional-electronic

Fully equipped master and feed spindle lathes. TH 4215 with digital position indicator DPA 21 / 3462070 - Hardened and ground Z-axis guideway - Spindle mount Camlock DIN ISO 702-2 No. 6 - Precisely crafted slide - Hand wheels with adjustable fine scaling 0.04 / 0.02 mm - Quadruple steel holder - All guides can be adjusted using V-ledges - Adjustment range top slide ± 90° - Guaranteed concentricity of the spindle nose better than 0.015 mm - Main spindle running in oil bath - Smooth-running gear wheels, hardened and ground with 2 adjustable Precision tapered roller bearings - Hand wheels decoupled and tested according to EN 23125 - Two-channel right-left switch tested according to EN 23125 - Switch with life cycle calculation, tested according to EN ISO 13849 - All metric pitches in the range 0.2 to 14mm/rev and all Inch threads in the range of 72 - 2 threads per inch without changing the Change gears adjustable by shift lever in the control panel - Clockwise/counterclockwise rotation can be switched on the bed slide via the switching spindle - Central lubrication in bed slide - Meehanite cast base and machine bed in one piece - Lead screw cover - Emergency stop device with foot control - Safety handwheels with snap-out function in the X and Z axes - Tailstock for taper turning adjustable ± 10 mm - Tailstock quill and hand wheel with adjustable fine scaling 0.025 mm - Quick, easy and tool-free adjustment using a clamping lever - Heavily ribbed prism bed, induction hardened and precision ground cast iron - Coolant device with separate coolant tank with level indicator and oil separator; easy and complete emptying and cleaning according to DIN - LED machine lamp in the chip guard Models TH 4210D and TH 4215D with digital readout DPA21 - User-friendly membrane keyboard, splash-proof, closed andglare-free - Glass scales scope of delivery - Fixed bezel passage Ø 15 - 145 mm - Revolving bezel passage Ø 10 - 75 mm - LED machine light - Reducing sleeve MT 6 / MT 4 - Fixed center MK 4 - Change gear set - Position stop with fine adjustment - Initial filling of the machine with quality oil - Operating tool ** Incl. special accessory OPTIMUM three-jaw lathe chuck centrically clamping Ø 250 mm ** Quick change holder SWH5-B set

- Lagernummer:

- 1125-2200008

- turning diameter:

- 560 mm

- turning length:

- 1910 mm

- swing diameter over bed slide:

- 355 mm

- Swingdiameter in the bed bridge:

- 790 mm

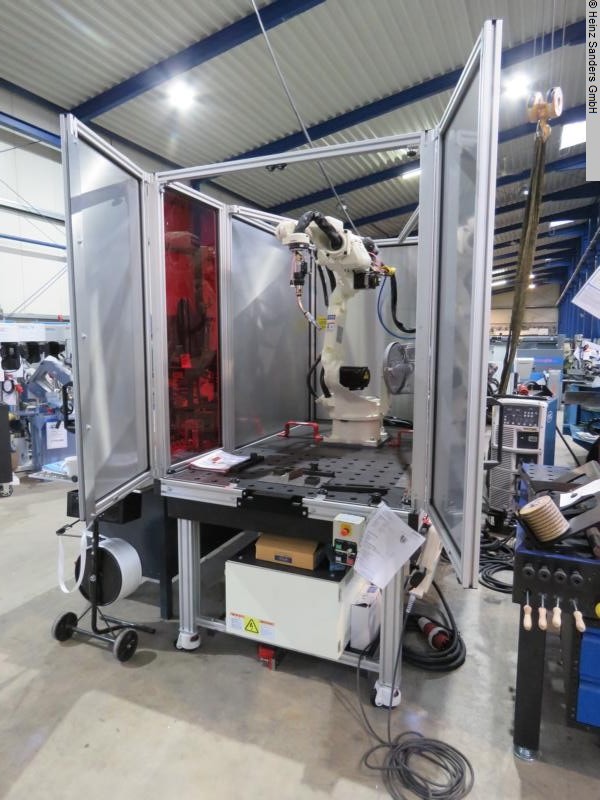

REHM

MegaPuls 300

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Welding machines

- Kategorie 3:

- Welding Unit

Year of construction 2020 **demonstration machine, as new** Easy ARC 01.02 FD-B6 Welbee P500L welding robot station MIG / MAG / water-cooled / torch RTW5000H / welding robot type FD-B6 with welding table 2000x1200mm Hole diameter 28 mm The mobile welding cell for the craft business Setting range MIG / MAG 20 - 500 A Steplessly adjustable switching levels Duty cycle at max.current 40 ° C 50% Current at 100% ED 40 ° C 410 A Wire feed speed 0 - 22 m / min

- Lagernummer:

- 1125-3450020

- length:

- 850 mm

- height:

- 975 mm

- total power requirement:

- 10,5 kW

- weight of the machine ca.:

- 175 kg

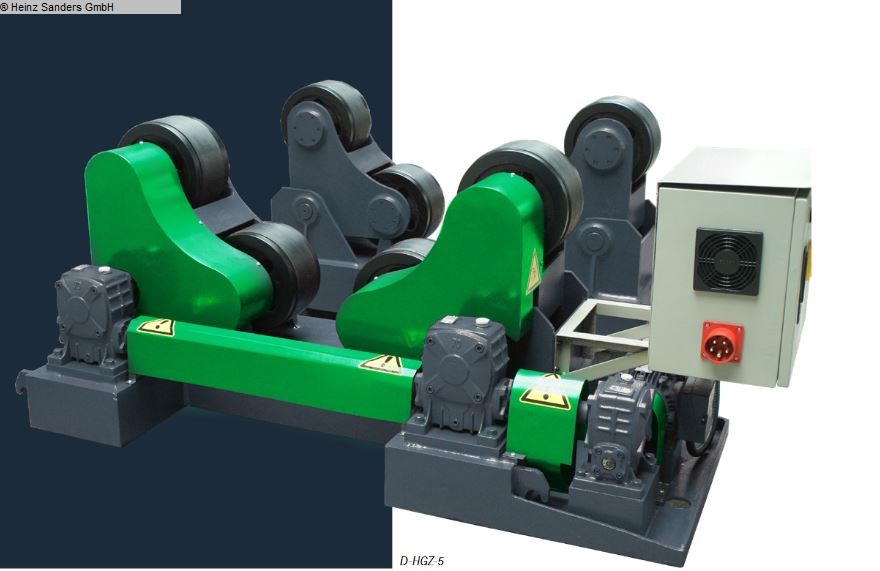

Dumeta

D-CHGK-5

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Sheet metal working / shaeres / bending

- Kategorie 3:

- Vessel Turning Unit

Incl. double foot pedal (start-stop / left-right) Incl. remote control (on the cable)

- Lagernummer:

- 1125-7295

- weight max.:

- 5,0 t

- workpiece diameter:

- 100 - 2500 mm

- total power requirement:

- 2 x 0,37 kW

- load capacity drive unit:

- max. 2500 kg

NKO

Anfassystem B22 ZERO

- Kategorie 1:

- Other Metal Processing

- Kategorie 2:

- Other machines

- Kategorie 3:

- Deburring Machine

Maximum chamfer width 20 mm + face machining Designed for chamfering and deburring straight edges, for the so-called FACING - removing an unwanted layer of material on the Front side of the workpiece, which is created, for example, by flame cutting a sheet metal. Specially developed for the production of visible chamfers and weld preparations. Powerful electric drive for extreme Charges. * High performance motor * stepless adjustment of the working angle in the range of 0° - 60° * FACING - Edge processing at an angle of 0° to remove unwanted ones Layers of material after flame cutting * The unique mechanical scale to adjust the bevel width for higher precision * A very compact and ergonomic design for high work productivity * Circumferential protective frame against damage and versatile grip options * With the appropriate accessories, pipes from D= 150 mm can also be processed * Additional adjustable handle - Chamfer width (hypotenuse): 0 - 20 mm = 400 Mpa / 0 - 16 mm = 400 Mpa - Motor: 1100W

- Lagernummer:

- 1125-2230013

- diameter:

- -- mm

- workpiece length:

- -- mm

- work piece width:

- 0 - 20 mm

- speeds:

- 2850 U/min

SIEGMUND

Extreme 8.7 2400 x 1200

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Welding machines

- Kategorie 3:

- Welding Table

The table Professional Extreme Article no. 4-280030.X7 2400x1200x200 mm has a hole arrangement in the 100 mm grid on the table top and a parallel hole arrangement in the 50 mm grid on the sides. The holes have a diameter of 28 mm and the table has a material thickness of about 24.5-27 mm. The table top is made of hardened tool steel. The low-loaded sidewalls are still made of steel S355J2 + N for cost reasons. Grid lines at a distance of 100 mm make it easier for you to set up your device. The welding tables are provided with scale as standard. Including 4x feet Basic equipment 650 Article no. 280858.X

- Lagernummer:

- 1125-5183X

- table length:

- 2400 mm

- table width:

- 1200 mm

- table height:

- 200 mm

- weight of the machine ca.:

- 1,0 t

METALLKRAFT

HSBM 1050-15 HSG

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Sheet metal working / shaeres / bending

- Kategorie 3:

- Folding Machine

Manual folding machine FSBM 1020-20 HSG / 3770103 - The workpiece is clamped using a foot pedal, so both hands remain free for material feed - Different tool variants available E, S2, HS2 and HSG - The strong auxiliary cylinder makes bending easier - Wide clearance between the upper and lower beam of up to 25 mm - Self-lubricating slide bearings - Clamping pressure of the upper beam can be easily adjusted using handy knurled screws - Adjustment of the material thickness by means of a knurled screw - Adjustable stop for bending angle Equipment details: FSBM 1020-20 HSG - With segmented goat foot tools, segmented bending bar and segmented bed pad - Segments have a hardness of HRC24-26 VA steel 1.2 mm Aluminum 2.4 mm

- Lagernummer:

- 1125-2350001

- sheet width:

- 1050 mm

- plate thickness:

- 1,5 mm

- distance between columns:

- -- mm

- weight of the machine ca.:

- 280 kg

PEDDINGHAUS

Peddimaster 60/100 H

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Sheet metal working / shaeres / bending

- Kategorie 3:

- Section Shear - Combined

Hydraulic machine with 5 stations so punching, notching, shearing flat iron, angle iron, solid material, punching with hand lever, profile steel side with foot switch. Punching discharge: 510 mm! All performance data refer to a material strength of 450 N / mm². Electric 380 volt

- Lagernummer:

- 1125-3410023

- round bar steel:

- 45 mm

- square edge steel:

- 40 mm

- L-beam:

- 120 x 13 mm

- flat steel:

- 500 x 12 mm

SIEGMUND

Professional 750 DR 3000 x 150

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Welding machines

- Kategorie 3:

- Welding Table

The Professional 750 4-280040.PD 3000x1500x200 mm table has a diagonal hole arrangement on the table top and a parallel hole arrangement in the 50 mm grid on the sides. The holes have a diameter of 28 mm. The table has a material thickness of about 24.5-27 mm and is made of high quality steel S355J2 + N. Grid lines at intervals of 100 mm make it easier for you to set up your device. The welding tables are provided with scale as standard. Including 6x feet basic equipment 650 Article no. 280858.X

- Lagernummer:

- 1125-4772DR

- table length:

- 3000 mm

- table width:

- 1500 mm

- table height:

- 200 mm

- weight of the machine ca.:

- 1,6 t

NKO

Anfassystem UZ12 ULTRALIGHT

- Kategorie 1:

- Other Metal Processing

- Kategorie 2:

- Other machines

- Kategorie 3:

- Deburring Machine

Chamfering system UZ12 ULTRALIGHT - KIT 30° + 45° Maximum bevel width 12 mm with automatic feed The UZ12 ULTRALIGHT is one of the lightest automatic beveling machines advance in the market. Thanks to its compact size and light weight it is not only suitable for workshops, but also for assemblies. The Machine is equipped with the automatic feed and therefore does this Working with the UZ12 ULTRALIGHT very comfortably. * For conventional steel (up to 600 MPA/87022 PSI strength), Brass, copper and aluminum materials * For chamfering workpieces with the minimum dimensions of 65 x 60 x 3 mm * Application range of sheet thickness 3 - 35 mm * Beveling of pipes from an inner diameter of 95 mm * Variable setting of the desired bevel using an exchangeable holder kit for any given angle * Double-sided bevel (X, K) with no material handling * Silent working * Equipped with an automatic feed * Stationary or mobile use * The machine works with large workpieces without any support a speed of 1.8m/min * Smaller workpieces are placed directly in the machine * Lightweight and compact design, handleable by one operator * Motor thermal protection - Max. bevel width (hypotenuse): 12 mm - Bevel angle: 30° / 45° / 22.5° / 37.5° / 50° (replaceable KIT) - Area of application sheet thickness: 3 - 35 mm - Motor: 400W - Feed speed: 1.8 m/min - Dimension: 470 x 294 x 523 mm ** We can also offer you an optional 3D manipulator (mobile) for this device on **

- Lagernummer:

- 1125-2230014

- diameter:

- -- mm

- workpiece length:

- -- mm

- work piece width:

- 12 mm

- range of angles:

- 30/45/22,5/37,5/50 °

EISELE

VMS 120

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Saws

- Kategorie 3:

- Cold Circular Saw

Manual metal circular saw MKS 315 N Action set / Item no. 3620303SET - two cutting speeds - Rotatable machine head 45° to the left and 45° to the right - Reduction gear, running quietly in an oil bath - automatic diaphragm coolant pump with coolant filter - Vice with counter vice, quick release and anti-burr jaws guarantees a precise and burr-free cut - Lateral material support arm with roller - Vice swivels 45° to the left and 45° to the right - Movable guard ensures optimal safety when cutting - Control handle with safety switch - Vice with counter vice, quick release and anti-burr jaws - Lateral material support arm with roller - Vise can be moved longitudinally and thus for longitudinal cuts and for suitable for slots 0° (round) solid material 55 mm 0° (round) tube 90 mm 0° (square) tube 80 x 80 mm 0° (rectangular) tube 115 x 70 mm -45° (round) solid material 50 mm -45° (round) tube 80 mm -45° (square) tube 70 x 70 mm -45° (rectangular) tube 70 x 70 mm +45° (round) solid material 50 mm +45° (round) tube 80 mm +45° (square) tube 70 x 70 mm +45° (rectangular) tube 70 x 70 mm

- Lagernummer:

- 1125-3160037

- saw blade diameter:

- 275 mm

- cutting diameter:

- 90 mm

- stroke:

- 250 mm

- turning speeds:

- 40 / 80 U/min

EHT / TRUMPF

TruShear 5063

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Sheet metal working / shaeres / bending

- Kategorie 3:

- Plate Shear - Hydraulic

Furnishing: - electric back gauge 750 mm - front support plates with ball rollers - Light barrier behind the machine - Hydraulic cutting adjustment - Cutting gap regulation via handwheel - LED cutting edge lighting - 1x side stop with scale 1500 mm - 1x freely movable foot switch - Operation manual

- Lagernummer:

- 1125-3320071

- sheet width:

- 3050 mm

- plate thickness:

- 6 mm

- rear stop:

- 10-1000 mm

- cutting angle:

- 0,5 - 2,5 °

RAGNAR

HYDR 5-36

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Threading machines

- Kategorie 3:

- Thread-Cutting Machine

- Lagernummer:

- 1125-7072

- thread dia.:

- M 5 - M 36 mm

- threading length:

- -- mm

- thread pitch:

- -- mm

- turning speeds:

- 0-100 U/min

OPTIMUM

OPTImill MT 50

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Milling machines

- Kategorie 3:

- Universal Milling Machine

Universal precision drilling and milling machine for horizontal and vertical milling work with digital 3-axis position display DPA 31 Plus Description: - Heavy, solid design made of high-quality, vibration-absorbing gray cast iron - Oil bath gear with ground, hardened gear wheels - Coolant system - Halogen machine lamp with bundled beam - Solid and large cross table, precisely surface-machined with T-slots and adjustable wedge strips - Milling head can be tilted ± 45° - Right/left rotation - X-axis moves either with the handwheel or via the table feed device - Automatic limit switch on the X-axis - Height-adjustable protective screen with microswitch, against flying chips and parts, for the greatest possible protection of the user Scope of delivery: - Gear rim drill chuck 1 - 16 mm / B 18 - Arbor drill chuck ISO40 / B18 - Horizontal milling spindle with counter bearing, disc milling cutter holder Ø22 mm, Ø27 mm - Adapter ISO 40/MK3 - Adapter ISO 40/MK2 - Vertical and horizontal drawbar - T-slot nuts - Drifter - Operating tool

- Lagernummer:

- 1125-2130001

- x-travel:

- 580 mm

- y-travel:

- 200 mm

- z-travel:

- 340 mm

- speeds:

- 115 - 1750 U/min

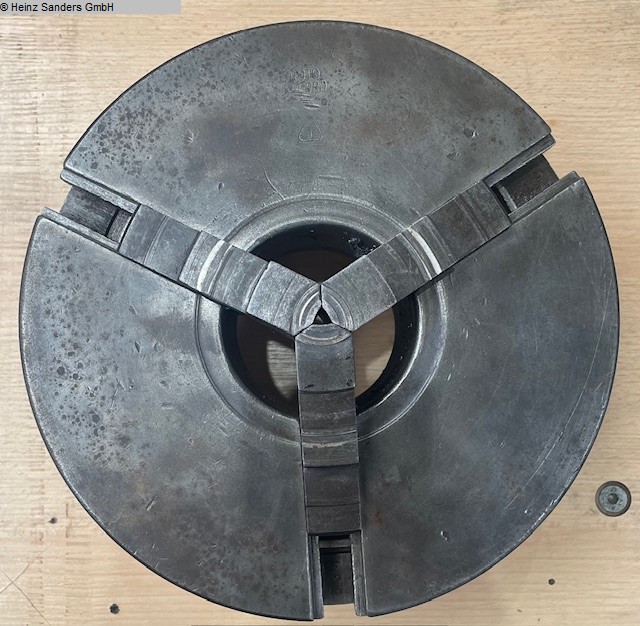

OPTIMUM

OPTIturn TH4215D

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Lathes

- Kategorie 3:

- lathe-conventional-electronic

Fully equipped master and feed spindle lathes. TH 4215 with digital position indicator DPA 21 / 3462070 - Hardened and ground Z-axis guideway - Spindle mount Camlock DIN ISO 702-2 No. 6 - Precisely crafted slide - Hand wheels with adjustable fine scaling 0.04 / 0.02 mm - Quadruple steel holder - All guides can be adjusted using V-ledges - Adjustment range top slide ± 90° - Guaranteed concentricity of the spindle nose better than 0.015 mm - Main spindle running in oil bath - Smooth-running gear wheels, hardened and ground with 2 adjustable Precision tapered roller bearings - Hand wheels decoupled and tested according to EN 23125 - Two-channel right-left switch tested according to EN 23125 - Switch with life cycle calculation, tested according to EN ISO 13849 - All metric pitches in the range 0.2 to 14mm/rev and all Inch threads in the range of 72 - 2 threads per inch without changing the Change gears adjustable by shift lever in the control panel - Clockwise/counterclockwise rotation can be switched on the bed slide via the switching spindle - Central lubrication in bed slide - Meehanite cast base and machine bed in one piece - Lead screw cover - Emergency stop device with foot control - Safety handwheels with snap-out function in the X and Z axes - Tailstock for taper turning adjustable ± 10 mm - Tailstock quill and hand wheel with adjustable fine scaling 0.025 mm - Quick, easy and tool-free adjustment using a clamping lever - Heavily ribbed prism bed, induction hardened and precision ground cast iron - Coolant device with separate coolant tank with level indicator and oil separator; easy and complete emptying and cleaning according to DIN - LED machine lamp in the chip guard Models TH 4210D and TH 4215D with digital readout DPA21 - User-friendly membrane keyboard, splash-proof, closed andglare-free - Glass scales scope of delivery - Fixed bezel passage Ø 15 - 145 mm - Revolving bezel passage Ø 10 - 75 mm - LED machine light - Reducing sleeve MT 6 / MT 4 - Fixed center MK 4 - Change gear set - Position stop with fine adjustment - Initial filling of the machine with quality oil - Operating tool ** Incl. special accessory OPTIMUM three-jaw lathe chuck centrically clamping Ø 250 mm ** Quick change holder SWH5-B set

- Lagernummer:

- 1125-2200001

- turning diameter:

- 420 mm

- turning length:

- 1500 mm

- swing diameter over bed slide:

- 250 mm

- Swingdiameter in the bed bridge:

- 590 mm

UNICRAFT

FHT 500

- Kategorie 1:

- Other Machines

- Kategorie 2:

- Other attachments

- Kategorie 3:

- Lift table

Sanders-Artnr. 10061751

- Lagernummer:

- 1125-6150500

- table length:

- 855 mm

- table width:

- 500 mm

- stroke height:

- 340 / 900 mm

- weight max. in kg:

- 500 kg

AWI

PAAV 10t 6000x2000mm

- Kategorie 1:

- Other Machines

- Kategorie 2:

- Other attachments

- Kategorie 3:

- Heavy Goods Trailer

Heavy-duty trailers - industrial trailers, available immediately from stock Frame: - Frame made of stable profile steel - Platform made of impregnated softwood - Protected all around with a steel edge, statically designed - 6 lashing rings welded on Steering: - The steering takes place via 2 axles with Ackermann steering - the steering drawbar is removable and can be hooked in on both sides - Steering angle approx. 42° - all rotating parts are with maintenance-free slide bearings (lubricated for life) Equipped with ball bearings - Towing eye: 40 mm Ø with wear ring - Fork support height adjustment for better coupling to the towing vehicle Wheels - the trailer is equipped with 4 heavy-duty wheels with elastic rubber covering Ø415mm, total width 200mm and ball bearings.

- Lagernummer:

- 1125-2540032

- :

- 10000 kg

- length:

- 6000 mm

- width:

- 2000 mm

- loading area height:

- 650 mm

BERNARDO

Proficenter 700 TOP

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Lathes

- Kategorie 3:

- lathe-conventional-electronic

Fully equipped master and feed spindle lathes. TH 4215 with digital position indicator DPA 21 / 3462070 - Hardened and ground Z-axis guideway - Spindle mount Camlock DIN ISO 702-2 No. 6 - Precisely crafted slide - Hand wheels with adjustable fine scaling 0.04 / 0.02 mm - Quadruple steel holder - All guides can be adjusted using V-ledges - Adjustment range top slide ± 90° - Guaranteed concentricity of the spindle nose better than 0.015 mm - Main spindle running in oil bath - Smooth-running gear wheels, hardened and ground with 2 adjustable Precision tapered roller bearings - Hand wheels decoupled and tested according to EN 23125 - Two-channel right-left switch tested according to EN 23125 - Switch with life cycle calculation, tested according to EN ISO 13849 - All metric pitches in the range 0.2 to 14mm/rev and all Inch threads in the range of 72 - 2 threads per inch without changing the Change gears adjustable by shift lever in the control panel - Clockwise/counterclockwise rotation can be switched on the bed slide via the switching spindle - Central lubrication in bed slide - Meehanite cast base and machine bed in one piece - Lead screw cover - Emergency stop device with foot control - Safety handwheels with snap-out function in the X and Z axes - Tailstock for taper turning adjustable ± 10 mm - Tailstock quill and hand wheel with adjustable fine scaling 0.025 mm - Quick, easy and tool-free adjustment using a clamping lever - Heavily ribbed prism bed, induction hardened and precision ground cast iron - Coolant device with separate coolant tank with level indicator and oil separator; easy and complete emptying and cleaning according to DIN - LED machine lamp in the chip guard Models TH 4210D and TH 4215D with digital readout DPA21 - User-friendly membrane keyboard, splash-proof, closed andglare-free - Glass scales scope of delivery - Fixed bezel passage Ø 15 - 145 mm - Revolving bezel passage Ø 10 - 75 mm - LED machine light - Reducing sleeve MT 6 / MT 4 - Fixed center MK 4 - Change gear set - Position stop with fine adjustment - Initial filling of the machine with quality oil - Operating tool ** Incl. special accessory OPTIMUM three-jaw lathe chuck centrically clamping Ø 250 mm ** Quick change holder SWH5-B set

- Lagernummer:

- 1125-2200007

- turning diameter:

- 300 mm

- turning length:

- 700 mm

- swing diameter over bed slide:

- 170 mm

- centre height:

- 150 mm

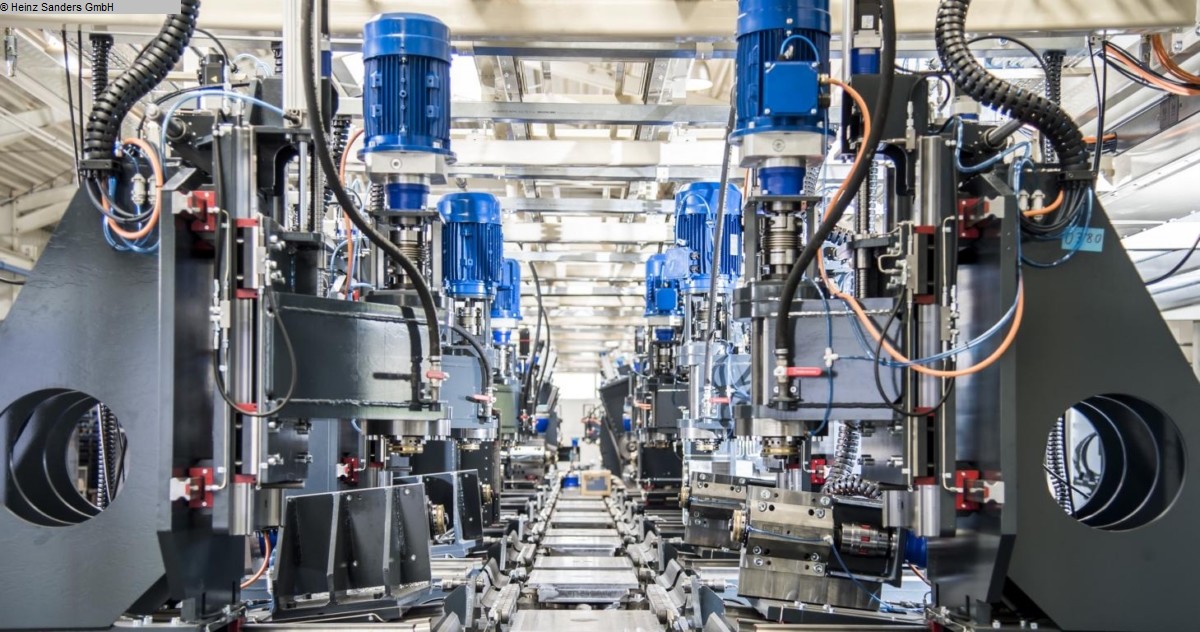

ELUMATEC

AS 70

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Milling machines

- Kategorie 3:

- Copy Milling Machine

*While stocks last* 4x hinges the pallet frames are foldable Weight: approx. 9.5 kg for 1200x800x200 mm

- Lagernummer:

- 1125-3540071

- x-travel:

- 230 mm

- y-travel:

- 90 mm

- z-travel:

- 110 mm

- turning speeds:

- 12000 U/min

ROMI

3000 x 6

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Sheet metal working / shaeres / bending

- Kategorie 3:

- Plate Shear - Hydraulic

Furnishing: - electric back gauge 750 mm - front support plates with ball rollers - Light barrier behind the machine - Hydraulic cutting adjustment - Cutting gap regulation via handwheel - LED cutting edge lighting - 1x side stop with scale 1500 mm - 1x freely movable foot switch - Operation manual

- Lagernummer:

- 1125-3320072

- sheet width:

- 3000 mm

- plate thickness:

- 6 mm

- rear stop:

- 1000 mm

- down holder:

- 18 Stk

ERMAK

CNC HGS 3100x6

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Sheet metal working / shaeres / bending

- Kategorie 3:

- Plate Shear - Hydraulic

----------------------------------------------------------- electr. / hydraulic CNC swing cut shears * with CYBELEC CNC touch screen control * with electr. / hydr. Kerf adjustment ----------------------------------------------------------- Furnishing: - CNC electr. / hydraulic swing cut shears - CYBELEC CNC touch screen controller, model CybTouch 8 * Backgauge preselection - X axis * Cutting gap adjustment * Number of pieces * Cutting length limitation * Material preselection, including sheet thickness * Cutting line lighting - motorized backgauge, travel = 1,000 mm (X axis) * on ball screws * autom. can be folded up at max.travel, for longer cuts - 1x side stop - 2x front support arms - Ball rollers in the front support table - hinged finger protection, with safety switch - BOSCH / HOERBIGER hydraulic system - SIEMENS electrical system - Light barrier behind the machine (safety device) - foot switch - CE mark / declaration of conformity - User manual: machine and control in German ** including special equipment: - pneumatic sheet metal holding device

- Lagernummer:

- 1125-2320004

- sheet width:

- 3100 mm

- plate thickness:

- 6 mm

- rear stop:

- 1000 mm

- cutting angle:

- 1,2 °

LAEPPLE

Sockel LC

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Presses

- Kategorie 3:

- Double-Column Presse

- Lagernummer:

- 1125-6847

- pressure:

- 50 t

- distance between columns:

- 2700 mm

- stroke:

- 800 mm

- table surface area:

- 2500 x 1600 x 150 mm

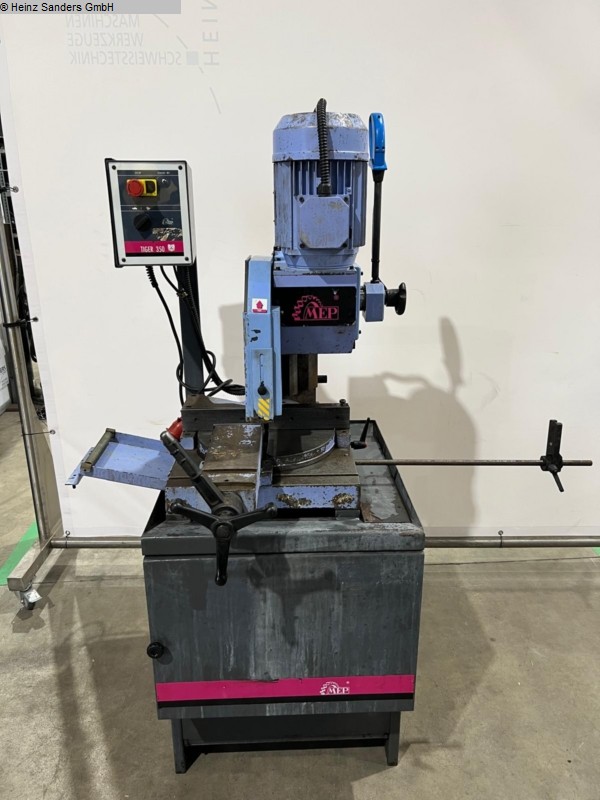

MEP

TIGER 350

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Saws

- Kategorie 3:

- Cold Circular Saw

-The powerful, 2-stage gear was specially designed for cuts in solid material designed -The user has a total of 4 blade speeds for optimal adjustment the material available -The large bearing rotary table with internal table clamping and Precision stops at 0/45/60° ensure quick adjustability miter cuts -The vice with quick clamping (optional is a pneumatic one Vise = MA, available) is with screwed vise jaws Mistake. With their ribbing, these ensure optimal hold of the workpiece -Underframe with lockable door, chip drawer and removable Coolant pan with electric coolant pump -Chip removal brush

- Lagernummer:

- 1125-3160041

- saw blade diameter:

- 350 mm

- dimensions of saw-blade:

- 350 x 32 x 2,5 mm

- cutting diameter:

- 115 mm

- stroke:

- 100 mm

KAI TEC

Plasmaschneidanlage 1500x3000

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Welding machines

- Kategorie 3:

- Flame-Cutting Machine

CNC plasma cutting system *NEW - AVAILABLE FROM STOCK* Furnishing: Cutting area 1,525 x 3,050mm Consisting of guiding machine, CNC control Plasma torch holder incl. torch height control, incl. Radio remote control and cross-laser for positioning, 1 license FastCAM programming software with Auto Nest Function and DXF,DWG import. Autogen set consisting of gas control solenoid valve, injector Machine torch torch holder, capacitive Height control, cutting range 10 - 50 mm plasma system Hypertherm Powermax 85 Sync CPC System Cutting range 1 - 20mm, cutting gas air Machine torch Smartsync 180° - 15.2 meters Machine is offered ex works. Without accessories (dye, anti-rust, aint mushroom, etc.) - further costs on request!

- Lagernummer:

- 1125-2500020

- table width:

- 1500 mm

- table length:

- 3000 mm

- burner heads:

- 1

- Control:

- CNC

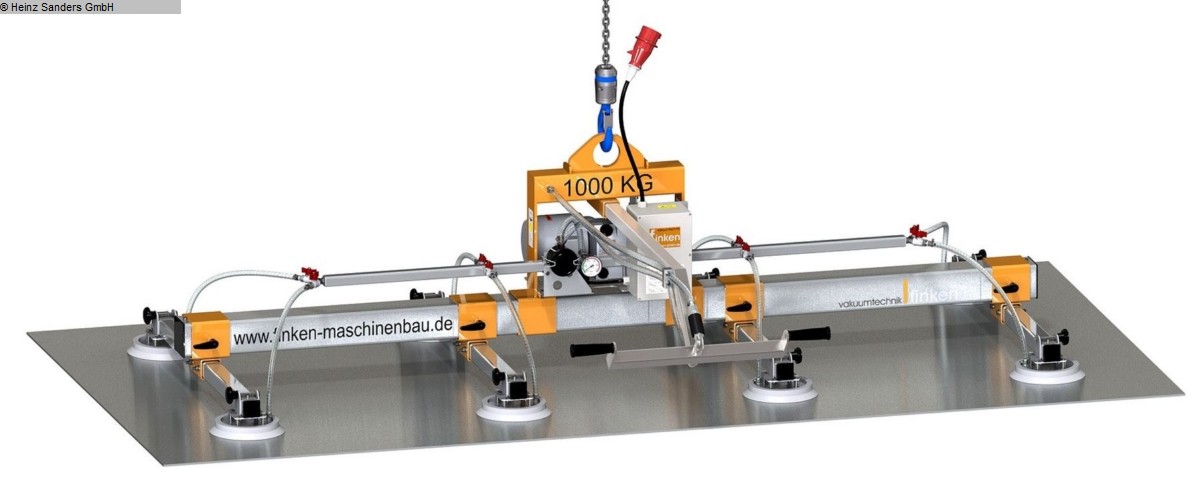

FINKEN

VH 6-250

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Sheet metal working / shaeres / bending

- Kategorie 3:

- Vacuum-Lifter

Vacuum lifter VH 6-250 for the horizontal transport of smooth, dry and airtight panels. Robust supporting structure made of steel, painted in RAL 2000 with low Own weight. consisting of: - 1x galvanized longitudinal beam with a length of 2,400 mm - 3x galvanized crossbeams with a length of 1,000 mm - 6x Springy, articulating and adjustable suction cup holders - 6x suction cups Ø 215 mm, the seal can be separated in case of wear whose metal supports can be changed inexpensively and without tools - 6x ball valves to switch off individual suction cups, thus also smaller formats can be lifted without having to move suction cups or traverses. - 1x spiral connection cable small helix: * with an extension length of 3,500 mm, designed as an extension cable with CEE plug and coupling. * is routed to the lifting device next to the load chain. - Low-maintenance, very high-quality, dry-running rotary vane vacuum pump a suction capacity of 8 m³/h and a final vacuum of 85% (150 mbar) - Electrical connection: 3 phases 230/400 V + PE, 50 Hz, with cable (approx. 0.5 m long) and CEE plug (16 A). Integrated into the control with isolating transformer (necessary if the vacuum lifter is connected via the crane trolley and this has no neutral conductor) - Operating handle can be extended to 1,000 mm from the center of the traverse. Sturdy sheet metal bag for your crane control incl. at no extra charge. - Operation "suction / release" using manual slide valve: The wear-free and very robust manual slide valve ensures safe Suction and release after pressing the release button. (twice loosening according to EN 13155) - Control and safety device for vacuum lifters: * Robust control box. * Contactor circuit for the vacuum pump. * Safety warning device with audible alarm. * Vacuum gauge with danger zone indicator. * Large vacuum storage tank with safety check valve * Double actuation when releasing the load. - Fine dust filter to protect the vacuum pump - Detailed and easy to understand documentation. One year warranty against material and manufacturing defects One-shift operation (without wearing parts). Initial test UVV 18, VBG 9a with CE declaration of conformity - according to EN 13155 - Packing for truck transport.

- Lagernummer:

- 1125-2530001

- carrying capacity:

- 250 kg

- number of suction cups:

- 6

- suction cup dia.:

- 215 mm

SANDERS

2000 x 400 mm

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Saws

- Kategorie 3:

- Roller tracks / stop systems

- Lagernummer:

- 1125-7211

- :

- 2000 mm

- Working width:

- 400 mm

- Wheel width:

- 400 mm

- roll diameter:

- 60 mm

FINKEN

VH 8-1000

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Sheet metal working / shaeres / bending

- Kategorie 3:

- Vacuum-Lifter

Vacuum lifter VH 8-1000 for the horizontal transport of smooth, dry and airtight panels. Robust supporting structure made of steel, painted in RAL 2000 with low Own weight. consisting of: - 1x galvanized longitudinal beam with a length of 2,400 mm - 4x galvanized crossbeams with a length of 1,000 mm - 8x Springy, articulated and adjustable suction cup holders - 8x suction cups Ø 280 mm, in case of wear the seal can be separated whose metal supports can be changed inexpensively and without tools - 8x ball valves to switch off individual suction cups, thus also smaller formats can be lifted without having to move suction cups or traverses. - 1x spiral connection cable small helix: * with an extension length of 3,500 mm, designed as an extension cable with CEE plug and coupling. * is routed to the lifting device next to the load chain. - Low-maintenance, very high-quality, oil-lubricated rotary vane vacuum pump with a Suction power of 21 m³/h and an ultimate vacuum of 98% (20 mbar). - Electrical connection: 3 phases 230/400 V + PE, 50 Hz, with cable (approx. 0.5 m long) and CEE plug (16 A). Integrated into the control with isolating transformer (necessary if the vacuum lifter is connected via the crane trolley and this has no neutral conductor) - Operating handle can be extended to 1,000 mm from the center of the traverse. Sturdy sheet metal bag for your crane control incl. at no extra charge. - Operation "suction / release" using manual slide valve: The wear-free and very robust manual slide valve ensures safe Suction and release after pressing the release button. (twice loosening according to EN 13155) - Control and safety device for vacuum lifters: * Robust control box. * Contactor circuit for the vacuum pump. * Safety warning device with audible alarm. * Vacuum gauge with danger zone indicator. * Large vacuum storage tank with safety check valve * Double actuation when releasing the load. - Fine dust filter to protect the vacuum pump - Detailed and easy to understand documentation. One year warranty against material and manufacturing defects One-shift operation (without wearing parts). Initial test UVV 18, VBG 9a with CE declaration of conformity - according to EN 13155 - Packing for truck transport.

- Lagernummer:

- 1125-2530003

- carrying capacity:

- 1000 kg

- number of suction cups:

- 8

- suction cup dia.:

- 280 mm

MEP

PH 261-1 HB

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Saws

- Kategorie 3:

- Band Saw

Compact, powerful workshop miter band saw machine for cuts from 0 ° to 60 ° left AUTOMATIC CUT: (via selector switch) with stepless settings of the Lowering speed and adjustment of the cutting pressure via compensating spring Description: -Manual cutting cycle and automatic cutting -AUTOMATIC CUT: (via selector switch) with stepless settings of the Lowering speed and adjustment of the cutting pressure via compensating spring -Stable, torsion-resistant and low-vibration saw frame made of cast steel -Vice with quick release - Carbide band guides for maximum cutting precision -Large dimensioned deflection discs, adjustable made of cast steel -Saw band tension with limit switch to check the correct band tension -Clearly arranged control panel with all controls -Electric coolant pump for cooling and lubricating the saw band -Schipping brush for cleaning the saw band

- Lagernummer:

- 1125-3916

- cutting diameter:

- 225 mm

- saw band length:

- 2450 mm

- table height:

- mm

- cutting width:

- 240 mm

FINKEN

VH 6-500

- Kategorie 1:

- Metal Processing

- Kategorie 2:

- Sheet metal working / shaeres / bending

- Kategorie 3:

- Vacuum-Lifter